Robotic Welding

Over the years, robotic welding has been utilized in various industries to increase productivity by automating production and ensure consistent quality. Traditionally, robotic welders required large investments in equipment and personnel training. Some of the reasons for using robotic welding are as follows: However, there are some disadvantages with traditional robotic welding as follows: The […]

Welder Qualification – Structural Steel Welding

The Australian Standard for Structural steel welding (AS1554.1 Sec 4.12.2.2) allows welders to be qualified by one of the following standards: · AS 1796 – Certification of welders and welding supervisors · AS/NZS 2980 – Qualification of welders for fusion welding of steels · AS/NZS 3992 – Pressure equipment—Welding and brazing qualification · ISO 9606-1 – Qualification testing of […]

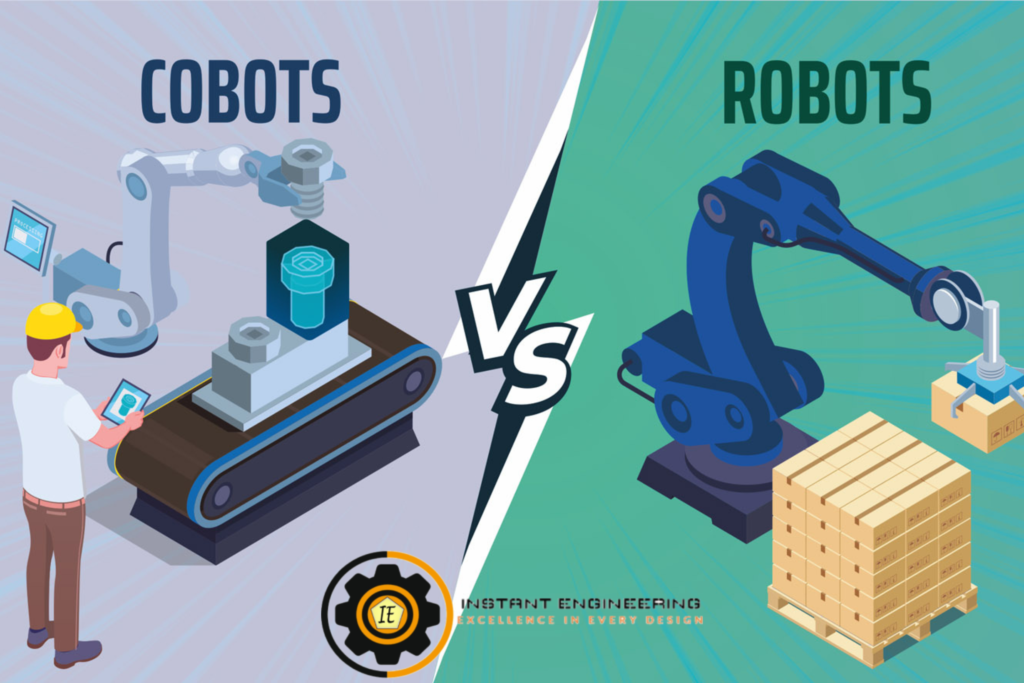

Difference between Cobots and Robots?

Robots can seriously hurt people in the way of its movements. Hence, extensive safety measures are required to ensure that people and robots are separated when the robot is in operation. Contrary to this, cobots, if obstructed will stop due to the inbuilt safety features. Therefore, they do not require extensive protection infrastructure. This allows […]

Methods of Preheating

Ceramic electric pads – surface of the part heated and then heat conducted through the part.

Applying direct flame – surface of the part heated using open flame and then heat conducted through the part.

Placement of part in a furnace – uniform heating of complete part if sufficient time provided in furnace, limitations of use due to the size of the furnace.

Induction heating – electromagnetic currents generate heat within the material.

Preheating before Welding

To reduce the risk of cracking in weld metal and heat-affected zone (HAZ), heating before actual welding is carried out. The level and need for preheat is determined by the applicable welding code and is dependent on the following: Preheating results in the following:

Are You Aware of the Requirements for Structural Steel Construction?

The much-awaited Australian Standard AS/NZS 5131 was released in December 2016 and sets out the minimum requirements for the construction of structural steelwork involving fabrication, corrosion protection, erection and modification. Before the release of this Standard, Australia did not have a dedicated Standard for fabrication and erection of steelwork. In Europe, a comparable Standard existed, which is […]